An automatic wood lathe is a machine that automatically turns timber into a predefined shape. This machinery was originally introduced in the 1870’s to enhance efficiency in woodturning production.

1870’s to enhance efficiency in woodturning production.

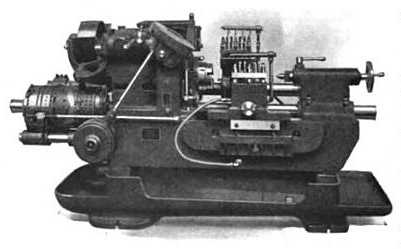

Early auto lathes were machines controlled by a mechanical linkage such as a cam or tracer. These earlier machines were also known as copy lathes as they were able to reproduce a turned shape by tracing an image or object.

Today the auto lathe is known as a CNC lathe controlled by computer. Sophisticated design (CAD) and manufacturing software (CAM) is used to program and operate the machine to produce the three dimensional output matching the design.

Capable of producing larger quantities in shorter time periods, the advent of the automatic lathe has resulted in a move away from the hand production method for large volume work. But even with automation a demand for hand turning still exists, particularly in smaller quantity and custom woodturning markets.

Hand turned products have a more well defined finish than those produced by automatic lathe. The shaped edges are sharper and there is less ridging with a smoother well sanded finish. This method can be more accurate in reproducing detail and may be a better for turning objects with specific or unique requirements.